Research

|

The Control, Instrumentation & Electrical System (CIES) Laboratory at The University of Western Ontario, in London, Ontario, Canada, was established in 2003 with financial support from the Canadian nuclear and electric power industries, and both the federal and provincial governments. CIES’ main research focuses on (1) instrumentation and control (I&C) systems for nuclear power plants (NPPs); (2) the control/integration of renewable energy resources in the form of distributed power generation; and (3) fault-tolerant control system design for safety critical system applications. In support of these research activities, two research labs have been established, each equipped with state-of-the-art facilities. Research sub-fields in the three areas identified above can be listed as follows: Nuclear Power Plant I&C Research

Distributed Generation (DG) Research - Control/integration of Renewable Energy Resources

|

|

|

Nuclear Power Plant I&C Research Overview |

||

|

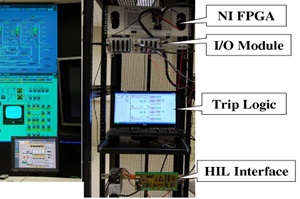

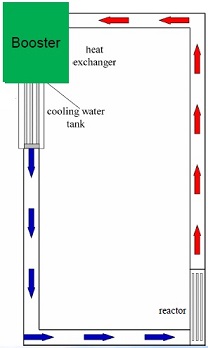

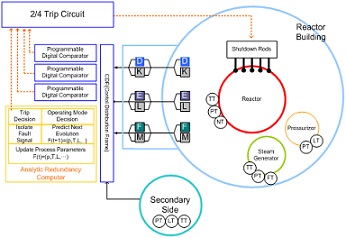

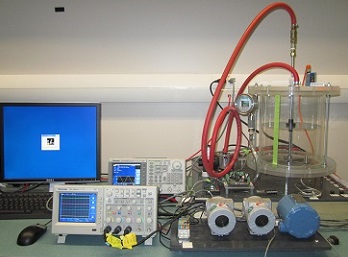

Area 1: Design and Analysis of Safety Systems One of the most important considerations in nuclear power system design and operation is safety. Every NPP contains systems dedicated to ensuring the plants safe operation, often known as systems important to safety, or simply safety systems. The ability of such systems to be available on demand is critical. One of CIES’ current research activities is on the reliability analysis of NPP safety systems under various conditions. The effects of hardware failures, functional failures, and deliberate sabotage, as well as ways in which such effects can be mitigated are the main focus of this research. In the event of a malfunction in any critical part of a nuclear power plant, it is important to shut the reactor down as quickly as possible. Before this can be done, however, it is necessary to deal with inevitable delays in several decision-making processes, such as sensor measurement, fault detection and diagnostics, and the final execution of shutdown actions. Even though there exist high-speed options for system implementation, there is always an upper limit to just how fast the reactor can be shutdown. One way to overcome this limit is to use ‘predictive’ techniques. The current research investigates the use of predictive shutdown systems, including prediction algorithms, quantification of uncertainties in the decision-making process, false alarm probabilities, and the effects of measurement noise on shutdown decisions. In order to meet the required availability on demand for safety systems, existing reactor protection systems often rely on Safety Programmable Logic Controllers (Safety PLCs) for decision-making processes. To achieve a high level of availability, redundant and parallel processing units (e.g. Triple-Modular Redundancy units) are often used in such systems. The implementation of reactor protection systems using such PLCs to achieve both high reliability and minimal decision-making delay is an important topic of research. Commercial grade Safety PLCs are employed in this research to ensure the research findings are relevant to current practical applications. The ultimate safety system for a nuclear power plant is a passive safety system where no additional intervention is needed to keep the reactor cool and maintain the system in a safe state. One such system is known as a passive residual heat removal system, which works on the principle of natural circulation. One drawback of such a system, however, is its weak driving force, which results in a low level of efficiency for heat removal. As such, current research is investigating ways to boost up the efficiency of such passive residual heat removal systems. |

|

|

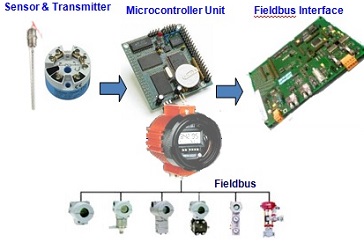

Area 2: Process Performance Monitoring and Fault Diagnosis In a complex system such as a nuclear power plant there are many things that could go wrong for various reasons, including hardware breakdowns, mis-operations, software errors, or the degradation of system components. Effective monitoring of system performance is therefore essential to quickly detect any abnormalities and correctly identify their root causes. Research in this area deals mainly with the development of effective performance monitoring schemes, such as time-frequency domain methods, Kalman filter-based innovation sequence algorithms, and pattern recognition techniques. Statistical approaches are frequently employed to cope with noise and the trade-off between false alarms and missed detection. The availability of mathematical models enables the estimation of lower stream variables using upper stream data in a dynamic process. Compared with hardware sensors, these models function as ‘analytical’ sensors, and can be treated as diversified sensor channels in a process known as ‘analytical redundancy’. One current research focus is the investigation of different forms of analytical redundancies, their applicability, advantages and disadvantages when deployed in a practical system. Most existing performance monitoring and fault diagnostic schemes are implemented centrally on either a Distributed Control System (DCS) or a dedicated computer system. The computing power of many contemporary transducers is high enough, however, that some performance monitoring and fault diagnostic schemes can be executed directly inside the transducer itself. By incorporating such ‘intelligence’ directly into the transducer, smart sensors and actuators can be realized. Performance monitoring and fault diagnosis can then be carried locally in a distributed way to avoid high volumes of data transfer between low level sensors and the high level DCS. Local measurements may not always be effective in achieving fault diagnosis in many practical situations. Additional remote measurements may provide much needed information to improve the performance of the diagnostics. Industrial wireless sensor networks provide an ideal solution for such situations, being relatively easy to install and enabling the acquisition of remote data necessary for diagnostic tasks. |

|

|

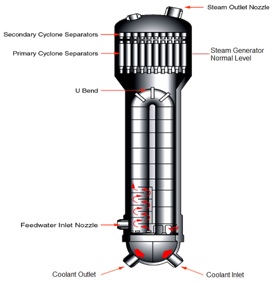

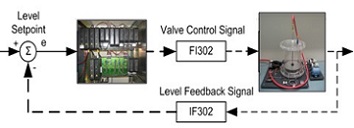

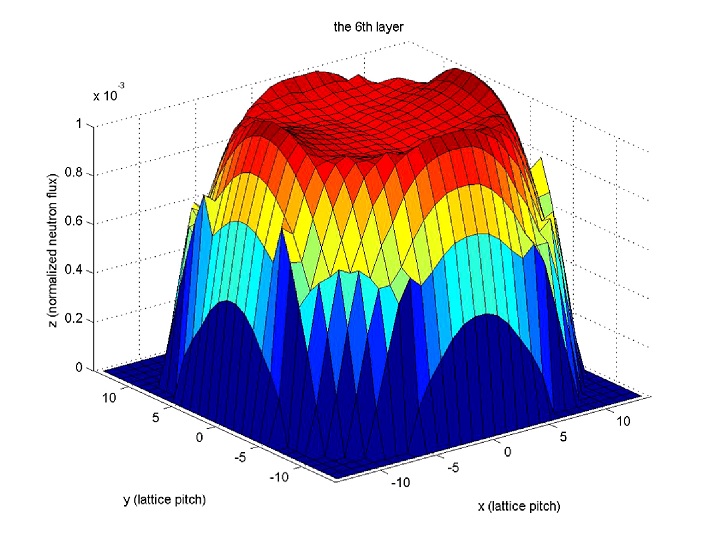

Area 3: Advanced Control System Technologies The first step in improving reactor control is to develop more accurate reactor models. Even though significant amounts of research and development work have been invested in reactor modeling over the years, most models are designed only for safety analysis or thermal hydraulic studies. Models for control system design and analysis have been limited to point kinetic equation representations or their variants. Due to the sheer physical size of a reactor, spatial information about the reactor has to be considered in the models for control system applications. Our research has developed two types of models for CANDU reactors: nodal models with coupling coefficients; and modal based 3-D models. In addition, we have also developed associated control systems based on these models. Amongst the key components in a CANDU or PWR reactor are its Steam Generators (SG). Steam Generators physically separate radioactive coolant in the primary loop from non-radioactive water in the secondary loop to prevent radioactive contamination of turbines, compressors, and other secondary side equipment. Due to bobbling effects, the dynamics of an SG are complex and have non-minimal phase characteristics. Advanced control algorithms have thus been developed for SGs, including both inverse dynamic control and model-predictive control. One way to improve thermal efficiency in the energy conversion process of a NPP is to operate it at higher temperatures and pressures. Within the framework of Generation IV (GEN IV) reactors, Canada has chosen to focus its nuclear power development program on supercritical water cooled reactors (SCWR). Since 2007, efforts have been made to develop dynamic models and control systems for Canadian direct-cycle SCWRs. The focus has been on model development, stability analysis, steady-state power regulation, and reactor control, as well as the start-up processes and reactor transient management. Traditional NPPs are large in size, and are normally operated in a mode of constant power output. With greater deregulation of the energy sector, coupled with the increasing use of new, often renewable energy sources, the unique advantages of small modular reactors (SMRs) are increasingly apparent. These advantages include greater flexibility, expendability, and lower initial investment than traditional NPPs. From an I&C perspective, the requirements for control of an SMR are quite different from that of larger units. For example, it is impractical to station each unit with the same numbers of personnel to operate the unit. The use of SMRs requires more autonomous operations. Furthermore, SMRs require the development of new sensing techniques as many SMRs adopt a highly integrated and self-contained design philosophy. Some variables commonly used in larger units may no longer be accessible in an SMR. Current research investigates the problem of multiple unit control and coordination, as well as I&C within each individual SMR unit. One of the biggest advancements in the last 20 years has been in communication technologies, and this has had significant impacts on I&C engineering. Industrial network-based control has revolutionized the way we access, analyze, and manage system data in real-time. The introduction of networks into control systems, such as fieldbus, industrial Ethernet, and other wired and wireless networks, poses new challenges, such as time delays, the risk of cyber-attacks, and other reliability issues. These topics have been investigated in the research group with special consideration given to nuclear power applications. Distributed Control Systems (DCSs) have become the control system of choice for new or refurbished nuclear power plants. Our lab houses four types of industrial grade DCSs: Siemens PCS7, Honeywell C300, Emerson DeltaV DCS, and HFC 1200. These systems, together with the NPCTF, allow researchers to examine the performance of their developed control schemes in a quasi-industrial environment. They also support research in other areas, such as network-based control systems and smart sensor development. |

|

|

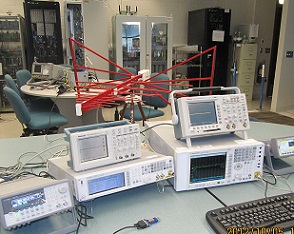

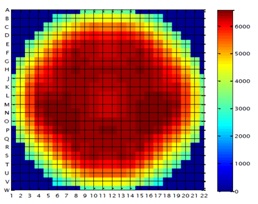

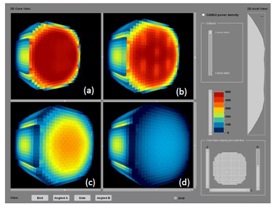

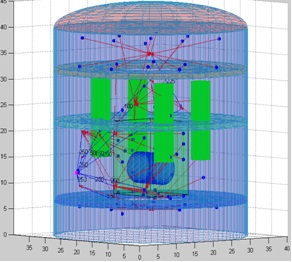

Area 4: Applications of Wireless Technologies in Nuclear Power Plants Research over the last decade has demonstrated the unique advantages of wireless industrial systems over wired systems. Despite this, acceptance of wireless technologies in nuclear power plant environments has been relatively slow for several reasons, including: (a) fear of wireless system interference with other sensitive equipment; (b) concerns about the robustness of wireless devices within a radioactive environment; (c) the complex geometrical and electromagnetic environments of wireless systems operating in; (d) a lack of deployment tools for wireless devices in an industrial setting, and (e) the need for seamless integration of both wired and wireless systems. All these problems are currently being investigated as a part of our research activities. It is important to mention that wireless sensor networks can facilitate data collection and provide an additional degree of freedom for overall plant monitoring and fault diagnosis during normal plant operations. In the event of an accident with limited human accessibility, wireless systems can be even more useful in providing up-to-date status on the plant and critical information regarding the accident. |

|

|

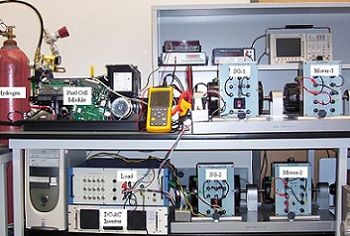

Distributed Generation (DG) Research Overview

|

||

|

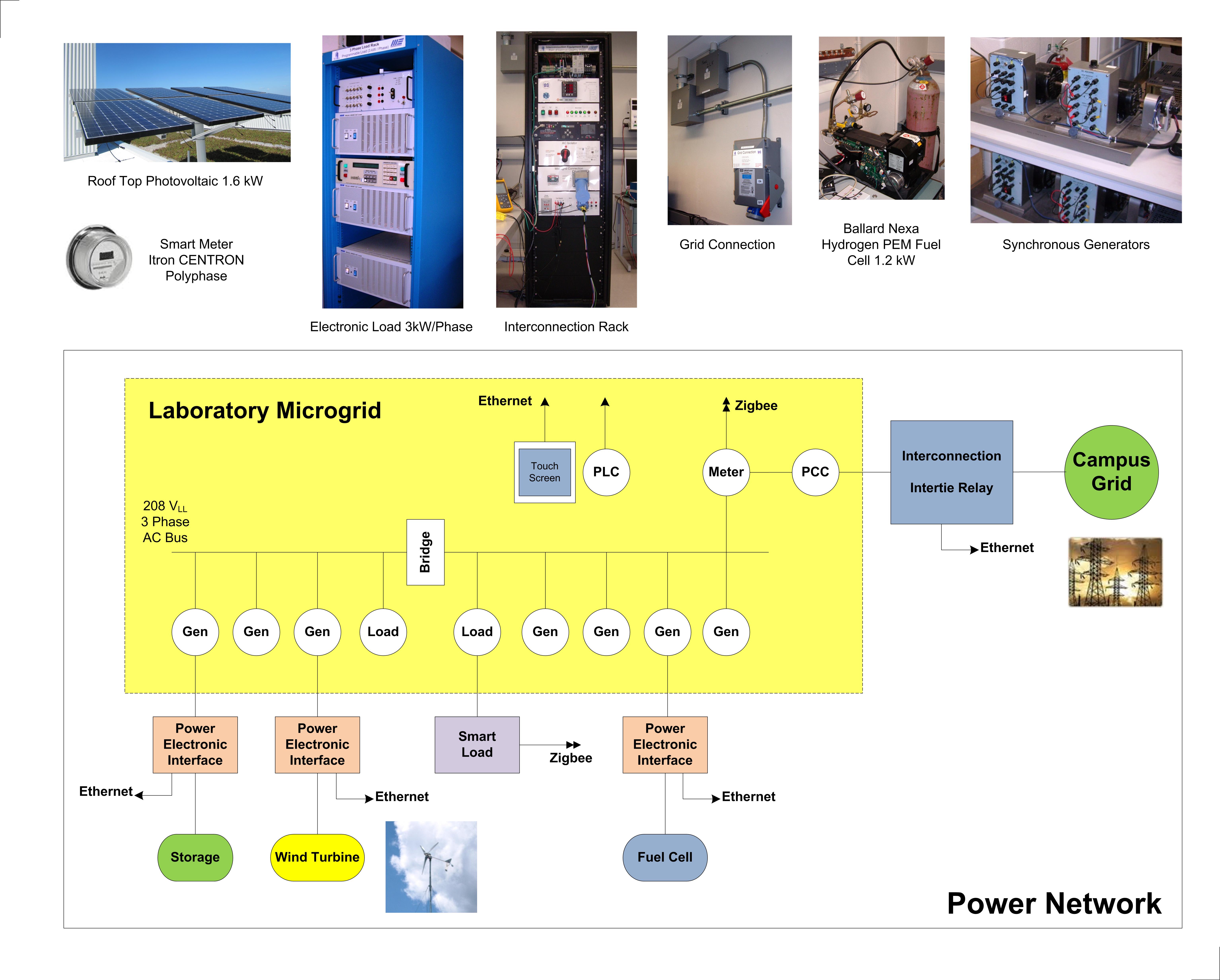

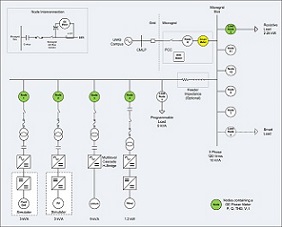

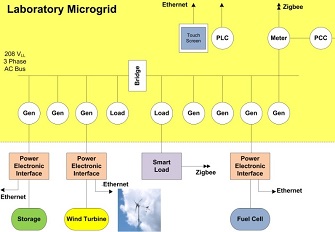

Area 1: Energy Management in Microgrids A microgrid may contain energy sources with very different characteristics. Many of these sources are non-dispatchable, such as PV or wind. When a microgrid operates in an islanded mode, controlling voltage and frequency, and achieving the desired energy balance becomes very challenging. Depending on control objectives, operational limits imposed by energy resources, the availability of storage devices, and load characteristics, different energy management schemes may be required. Current research is investigating and evaluating such schemes, looking in particular at the stability and voltage profile of microgrids and carrying out the design and implementation of power electronics converter-based control systems. |

|

|

Area 2: Control and Integration of Non-dispatchable Renewable Resources One of the major drawbacks of some forms of renewable energy, such as solar and wind, is that they are less predictable than traditional sources and are therefore essentially non-dispatchable. As a result, it is difficult to depend on such sources to supply a load with specific characteristics. Under such circumstances, one either has to rely on other dispatchable energy sources or make use of energy storage devices. The objective of this research is to investigate the coordination and control of energy storage devices to increase the penetration of non-dispatchable renewable energy in total energy portfolios. The research involves modeling, control and coordination of renewable resources and battery storage devices to match particular load characteristics. |

|

|

|

Area 3: Intelligent Control of Photovoltaic Systems Even though the effectiveness of PV power systems depends largely on the level of solar irradiance and ambient temperature, the overall performance of a PV system (with multiple PV modules) also depends on how the individual modules are connected, as well as how power electronic converters are configured. These problems become paramount when partial shading occurs on some of the modules, most often in the case of building-integrated PV (BIPV). BIPV systems are installed as an integrated part of a building, which may not be optimal for PV power generation. Research has been carried out to understand the effects of partial shading on PV generation, and to develop new control techniques to extract maximum power from such systems under various non-ideal conditions. The evaluation platform supporting this research includes physical roof-top PV modules and PV simulators, as well as power electronic control development systems. |

|

|

Area 4: Wind Turbine Control Systems Unlike PV, where the movement of clouds and changes in the solar irradiance throughout the day are relatively slow, wind stream can change rather rapidly. Ensuring the stable operation of wind turbine systems under various wind conditions requires dealing with such unique characteristics in the control system design and implementation stage. Reactive power control for wind turbine systems is also a major issue. The objective of this research is to investigate the dynamic characteristics of wind turbine systems and to determine the optimal strategies for incorporating wind energy into a microgrid in both grid-connected and islanded operation modes. This research is supported by a physical wind turbine simulator as well as an actual roof-top wind turbine. |

|

|

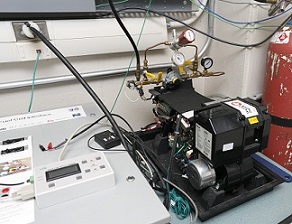

Area 5: Integration of Fuel Cell Power Module and Battery Storage In order to provide adequate support for microgrid operation under different load conditions, current research considers two types of dispatchable alternative energy resources. One is a fuel cell power source, while the other is battery storage, including the use of super-capacitors. The fuel cell power module can effectively provide power to the load in the microgrid when renewable resources are insufficient to balance the load demand, while batteries can be used to either supply additional energy or absorb surplus energy within the microgrid. Since the dynamic characteristics of the fuel cell power modules are inherently much slower than the charging and discharging of batteries, integrating both in a microgrid environment poses unique challenges and opportunities. |

|

|

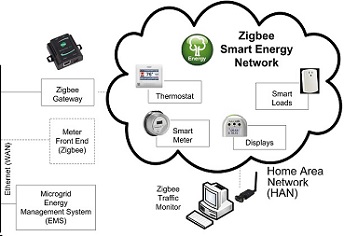

Area 6: Smart Homes and Load-side Management One of the most important goals of a smart distribution system is empowering consumers to make their own decisions and change patterns of their energy consumption collectively. While these objectives can be accomplished through real-time pricing or pre-negotiated contracts, implementing such a schedule requires a sound decision-making process, and the hardware support to link real-time pricing information from smart meters to energy-intensive home appliances, in order to alter patterns of electricity use. Current research includes the development of wireless enabled devices to facilitate consumer participation in load-side management in a smart home environment. |

|

|

|

Fault-tolerant Control Systems

|

||

|

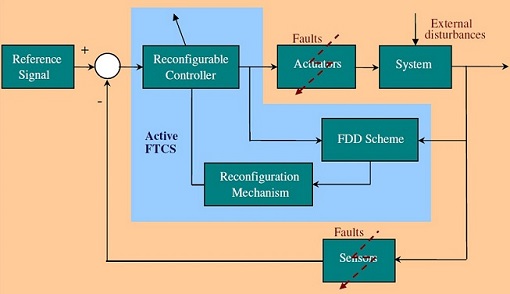

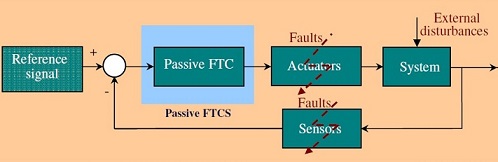

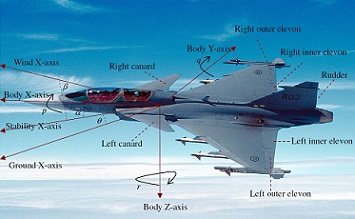

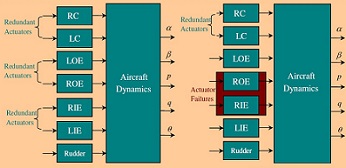

Area 1: Design and Implementation of Industrial Fault-tolerant Control Systems Despite extensive research on fault-tolerant control systems, most work done so far in this field has been at a theoretical level, with very few successful practical applications. The main reason for this is the presence of too many unrealistic assumptions made at the theoretical level. Practical hardware limitations or the failure modes of practice systems are all too rarely considered in such research. Our current research has focused on the practical issues of actual physical systems, examining their potential failure modes through systematic analysis, identifying vulnerabilities, and designing effective fault-tolerant control techniques. The goal of such research is to create fault-tolerant control system design methodologies and techniques for practical industrial processes.

|

||

|

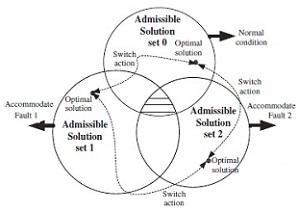

Area 2: Management of Physical and Analytical Redundancies The concept of defense-in-depth is at the core of any fault-tolerant control system. In practice, however, it may not always be possible for physical redundancies to cover all conceivable failure modes. One alterative solution is to trade-off redundancies for allowable performance degradation to ensure the maintenance of the system’s most important features, such as stabilities. Furthermore, the availability of mathematical models (analytical redundancies) can play a critical role in restoring missing information using either upper stream or neighboring measurements. The objective of this research is to investigate how physical and analytical redundancies can be effectively managed to achieve fault-tolerance in the design control systems. |

|

|

Area 3: Fault Detection and Diagnosis for Fault-tolerant Control Systems Despite the presence of numerous fault detection and diagnosis methods in the literature, their practical application remains relatively limited. One reason for this is because most of these algorithms have been developed in an academic setting without taking full account of the limitations and measurement constraints in practical systems. Our current research examines the faults and their respective effects first and foremost from a physical and logical point of view. This allows us to better identify not only the key features of the faults but more desirable measurement locations as well. Such knowledge enables more effective detection and diagnosis of faults, which in turn enables the design of effective fault-tolerant control systems. |

|

|

|

Area 4: Self-power Safety Systems One reason why disasters happen in a practical system, for example, plane crashes, nuclear reactor meltdown, is because the system contains significant amount of energy (potential energy of a flying plane case, and thermal energy in an operated nuclear reactor). In the meantime, one loses control of the systems, often due to lack of adequate controlling energy. This research examines ways that one can effectively channel the excessive energy through a proper means to convert “destructing energy” into “energy for control” to enhance the system safety, rather than letting it causes destructions to the system. Self-power safety systems are the best and ultimate ways to deal with situations when an airplane loses its power and a reactor loses its cooling capabilities. |

||

|

Area 5: Safety Systems and Cyber-physical Systems Manipulation of data or unauthorized changes to system operating conditions pose serious security threats to cyber-physical systems. Such threats can be very difficult to detect if carried out by an insider with access to and familiarity with the system. Current research examines ways to identify vulnerabilities in cyber-physical systems and develop tools to improve system security through fault-tolerant techniques and defence-in-depth concepts. The methods developed are intended for applications in safety critical systems, such as nuclear power plants or electric power grids. |

||

|

All rights reserved. 2015-2016

Phone: (519) 661-2111 Ext. 88320; Fax: (519) 850-2436; E-mail: jjiang@uwo.ca Office: TEB 333, Electrical & Computer Engineering, Faculty of Engineering The University of Western Ontario, London, Ontario, Canada N6A 5B9 |